Mechanized giants: the paper-making machines

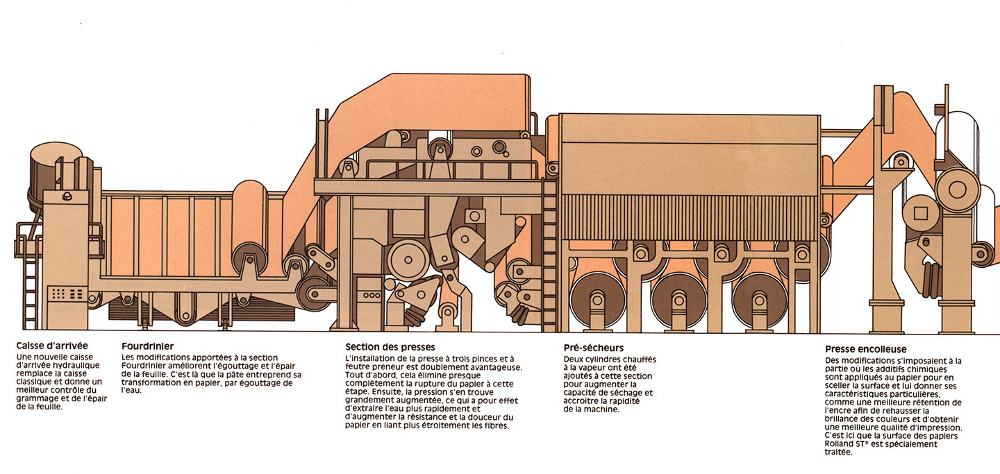

The paper-making machines were the heart of operations at the two Rolland Company mills. They turned rag pulp, the basic ingredient in most types of paper, into the consistency of a sheet. At first, these machines were water-powered, by the current of the Rivière du Nord. Machine No. 1 was installed at the Saint-Jérôme mill in 1883, and the first sheets of Superfine Linen Record paper were made with it.

To meet the increasing demand for fine papers and expand its product range, the company installed other, increasingly efficient, equipment. For many years the Saint-Jérôme plant operated with four machines (numbers 1, 2, 5 and 6), while the Mont-Rolland facility had only two (numbers 3 and 4).

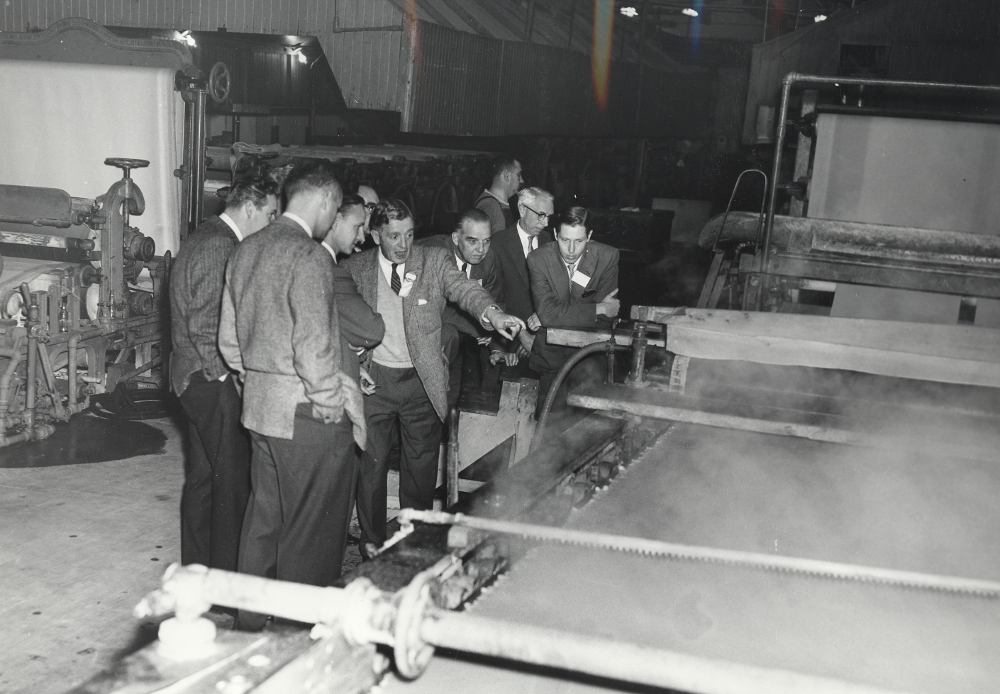

The No. 7 and No. 8 machines were added to the Saint-Jérôme plant in 1957, and the first two—by then obsolete—were retired. At the time, No. 8 was the largest, most modern paper machine in Canada, and cost the company $7.5 million to install. In one week, this one machine could produce enough paper to lay a 14-foot-wide road from Vancouver to Halifax. The daily output of the machines at Saint-Jérôme was 200,000 pounds of paper, the equivalent of five freight wagons.

Keeping pace with advances in technology, the machines were retrofitted to produce new products. Besides fine papers, Rolland marketed various specialty papers: Bible paper (also called India paper) as well as photocopying and printing papers (known as the Bond and Offset lines). In addition, paper for cigarette filter tips was produced on Machine No. 6 for many years.

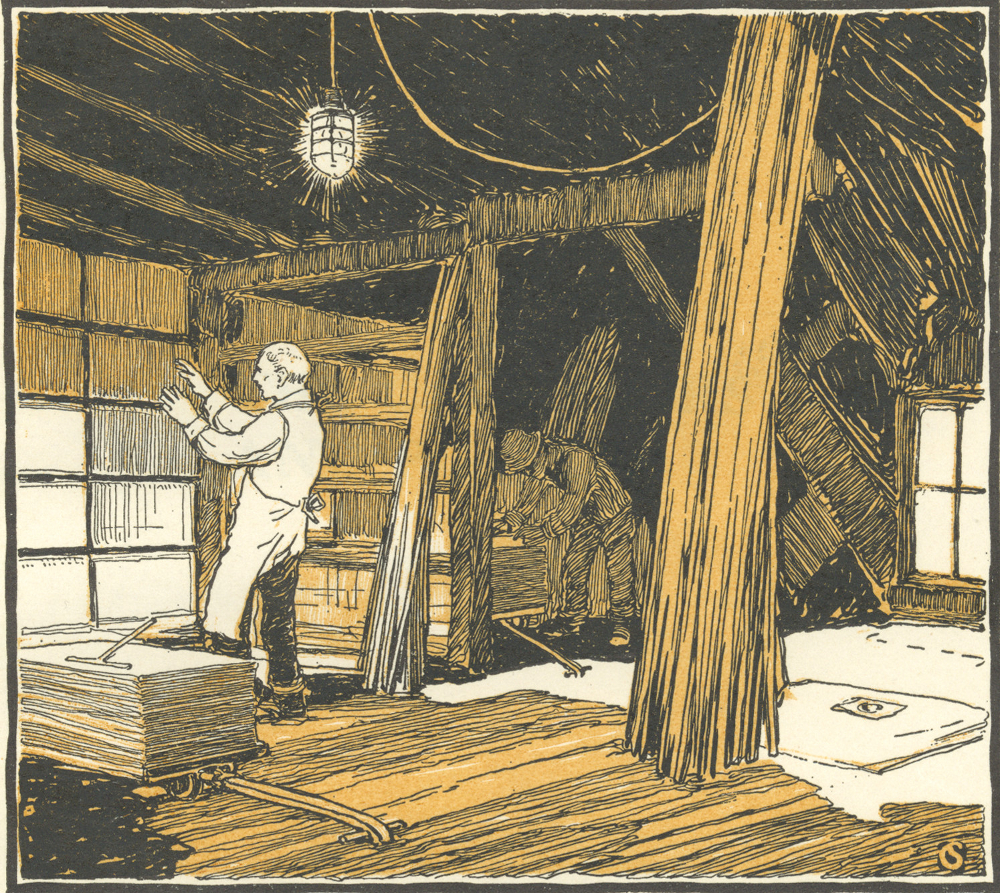

The machines also became more and more efficient. Some steps in the production process, such as drying—originally done by hanging the sheets from wooden rods—were entirely mechanized.