Rock Hauling

After uncovering and breaking up limestone layers, the rubble must be transported to processing structures and the market.

To Kilns and to Market

Early on, lime burners used buckets or wheelbarrows to transport stone to the flames. In the late 1800s, horse-drawn carts or wagons were used as operations expanded.

In this era, wagons were integral for delivering lime and limestone products. The products were bagged and shipped. By December 15, 1853, the railway in Beachville facilitated the transportation of supplies, equipment, and products to and from the quarries.

Inside the Pit: The Derrick

In the late 1880s, as quarry pits expanded and stone was transported to more distant markets, the Downing-Bremner quarry introduced a derrick to lift stone into wagons or awaiting railway cars.

Marjorie Cropp, one of Beachville’s most well-known local historians, described the derrick in her text, Salute to Oxford:

It was a ponderous affair raised on tresles, the whole set on a platform on wheels running east-west on a track just below the north face. Its long arm (boom) could pick up full buckets…over the north rim of the pit and empty them into freight cars standing on the railway siting above.

These derricks inspired the steam shovel design, which became essential for quarry excavation in the 1900s.

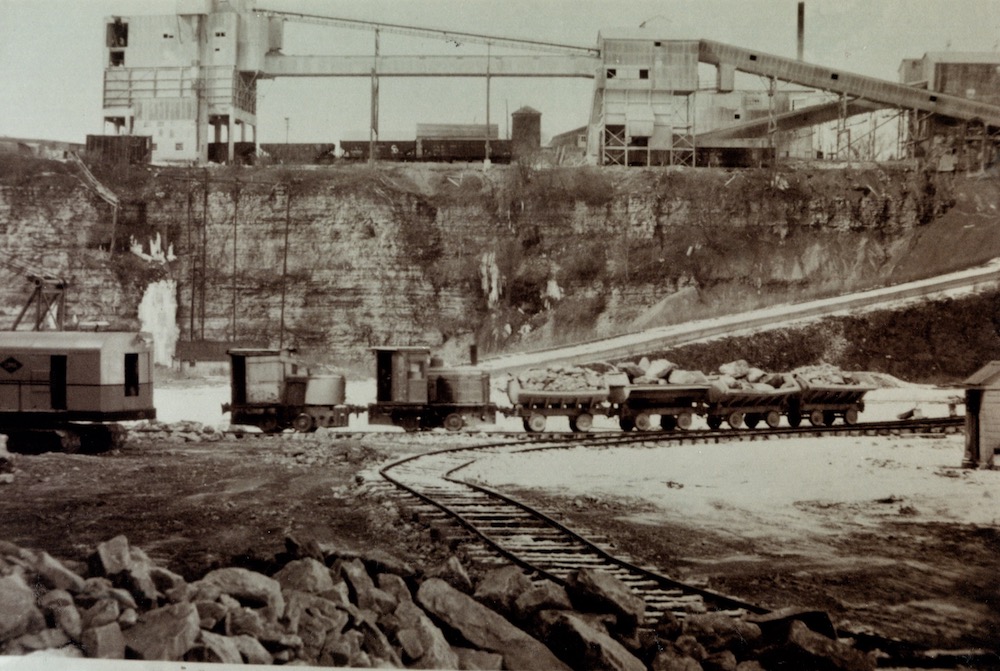

Tracks and Tramways

Tracks were laid at the bottom of pits so horse-drawn carts loaded with stone could be pulled toward the crushers and kilns. At Beachville White Lime, stone was shovelled into carts brought up the main incline from the pit to the crusher on cables manually. In 1912, Standard White Lime laid a larger track circuit for a locomotive to pull 5 dump carts. A 200-horsepower electric mine hoist was installed, pulling 20 quarry carts to the crusher per hour, exceeding the manual pulling speed.

After leaving the crusher, limestone underwent the other processing stages along a network of conveyors. Then, it was loaded into hopper cars, each carrying around 60 tons of limestone. These cars were picked up once a day, 6 days a week.