2

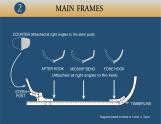

After the backbone assembly was secured, the three mainframes - the fore hook, mid-ship bend and after hook - were made. These three frames determined the shape of the boat. The three-piece-mould or half-mould methods would be used to determine the shape of each frame. Two pieces of timber would then be chopped, sawn, and planed to the required dimensions and then butted together at the base using a floor piece fastened to one side of the timbers. The timber pairs were attached temporarily across the top with a board to ensure stability and alignment during construction. The three mainframes were then ready to be located and fastened to the keel.3

Mid-ship bend (bottom) and fore hook (top)2003

Winterton Boat Building and Community Museum, Newfoundland and Labrador, Canada

4

At this point a decision had to be made about the location of each main frame along the keel. This decision would affect the final shape of the hull. The fore hook was usually placed at the point on the keel that was the same distance from the stem at the sheer line (top of the hull) as the width of the fore hook itself. The mid-ship bend was placed at the mid point of the hull, though some builders liked to move it an inch or two forward of this mid point.5

Mid-ship bend (bottom) and after hook (top)2003

Winterton Boat Building and Community Museum, Newfoundland and Labrador, Canada

6

The after hook would normally be placed forward of the counter at a point that was the same distance from the counter, along the sheer line, as the width of the after hook itself.When installing the permanent timbers, each pair would be notched into the keel to the timberline previously marked on the keel. The timbers were held in place by nailing them to the keel and with temporary spans to the floor or pegs driven into the ground.

7

Attaching battens2003

Winterton Boat Building and Community Museum, Newfoundland and Labrador, Canada

8

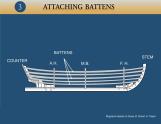

Full-length battens were then attached with nails, from stem to counter (horizontally) around the mainframes. The battens, which are long boards, two or three inches wide and less than an inch thick, would be spaced eight to twelve inches apart with five or six on each side. Battens and main frames gave the hull shape along the full length of the boat and were used to get the shape of each additional pair of timbers.9

Attaching battens2003

Winterton Boat Building and Community Museum, Newfoundland and Labrador, Canada

10

The top battens nailed to the three frames, counter and stem.11

Attaching battens2003

Winterton Boat Building and Community Museum, Newfoundland and Labrador, Canada

12

The second row of battens attached to the three frames.13

Attaching battens2003

Winterton Boat Building and Community Museum, Newfoundland and Labrador, Canada