14

All of the battens attached to the stem (front of the boat).15

Attaching battens2003

Winterton Boat Building and Community Museum, Newfoundland and Labrador, Canada

16

All of the battens attached to the counter (back of the boat).17

Timbering out2003

Winterton Boat Building and Community Museum, Newfoundland and Labrador, Canada

18

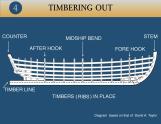

With the battens attached horizontally across the length of the boat the shapes needed for the vertical timber pairs could be found. Typically in a small motorboat of 20 feet or so in length, timbers were placed eight to twelve inches apart with four or five timbers between each of the mainframes and in each end section of the boat.19

Finding the shape for a timber2003

Winterton Boat Building and Community Museum, Newfoundland and Labrador, Canada

20

The shape of these timbers was usually obtained by using a slim, long, rod of lead (copper was used here), which would be pushed against the battens on either side where the timber was to be installed. When the lead rod was removed it would retain the needed shape.21

Selecting the correct timber piece2003

Winterton Boat Building and Community Museum, Newfoundland and Labrador, Canada

22

The shaped lead rod would then be carried to the already sawn slabs of curved wood. The piece closest to the rod shape would be selected for making the timber. Laying the rod on the flat surface of the wood the builder drew lines to mark the timber shape. The timber was then roughly cut out using a handsaw and axe.Often timbers were made from one single piece of wood for each side. However, joining pieces together was not unusual and often necessary for larger boats. Timber sections were joined by nailing another shorter piece to one face of each joining timber piece in effect making the timber twice the thickness near the joint.

23

Sawing a timber2003

Winterton Boat Building and Community Museum, Newfoundland and Labrador, Canada

24

Sawing the curve of the timber with a lock saw (keyhole saw).25

Lock saw (keyhole saw)2003

Winterton Boat Building and Community Museum, Newfoundland and Labrador, Canada

26

Before power tools, a lock saw (keyhole saw) was essential to cut along difficult curves on timbers.27

Using a bench vise2003

Winterton Boat Building and Community Museum, Newfoundland and Labrador, Canada