14

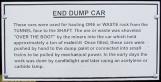

End Dump Car10 April 2006

The Heritage Silver Trail, Town of Cobalt and Coleman Township, Ontario, Canada. Site #20

15

Compressed Air Trammer9 April 2006

The Heritage Silver Trail, Town of Cobalt and Coleman Township, Ontario, Canada. Site #20

16

Compressed Air Trammer9 April 2006

The Heritage Silver Trail, Town of Cobalt and Coleman Township, Ontario, Canada. Site #20

17

Compressed Air trammer, front9 April 2006

The Heritage Silver Trail, Town of Cobalt and Coleman Township, Ontario, Canada. Site #20

18

Compressed Air Trammer (Loco)Compressed air was readily available in the Cobalt mines making the air locomotive an economical haulage option.

19

Cage10 April 2006

The Heritage Silver Trail, Town of Cobalt and Coleman Township, Ontario, Canada. Site #20

20

Cage and Skip10 April 2006

The Heritage Silver Trail, Town of Cobalt and Coleman Township, Ontario, Canada. Site #20

21

Cage and Skip10 April 2006

The Heritage Silver Trail, Town of Cobalt and Coleman Township, Ontario, Canada. Site #20

22

Cage and SkipThe unit in the picture would have had a skip mounted above the cage and this would have remained there all the time. The problem with this type of system means the cage cannot be used when hoisting ore and the skip cannot be used when using the cage. This particular unit was made at a local foundry and used in a local mine for several years.

23

Skip10 April 2006

The Heritage Silver Trail, Town of Cobalt and Coleman Township, Ontario, Canada. Site #20

24

The Skip10 April 2006

The Heritage Silver Trail, Town of Cobalt and Coleman Township, Ontario, Canada. Site #20

25

Sinking Hoist10 April 2006

The Heritage Silver Trail, Town of Cobalt and Coleman Township, Ontario, Canada. Site #20

26

Sinking HoistThe mine hoist would be set up on a timber or concrete base and then a house built over it for protection from the elements. Hoists in Cobalt tended to be relatively small as the shafts were not deep (200-300ft) and prospect shafts even smaller. The hoists were operated by a hoist engineer who usually maintained the equipment as well. The operator communicated with the users by means of signals given by bells through a bell cord on a series of pulleys. Each sequence of bells meant a different action to be taken by the hoist man. Two bells and two bell meant hoist to surface followed by a one bell signal which was the signal to move. The hoist man knew where the shaft conveyance or bucket was at all times by means of an indicator dial connected to the drum. The speed of the drum would result in the conveyance moving at about 300 feet per minute.

27

Sinking Hoist10 April 2006

The Heritage Silver Trail, Town of Cobalt and Coleman Township, Ontario, Canada. Site #20