5

Of course, such an undertaking had people talking. Imagine a priest implanting a factory in a church... No need to worry though, the steeple, the bell, the sacred objects, the candlesticks, the statues, the lamps and the high altar were all moved to the new church before the factory was up and running.

6

Figurine of St. Ignace of Loyola18th century, circa 1742

Batiscan (Quebec), Canada

Credits:

Credits:Collection of the Musée national des beaux-arts du Québec

7

Statue of St. Joseph18th century, circa 1734

Batiscan (Quebec), Canada

Credits:

Credits:Collection of the Musée national des beaux-arts du Québec

8

High altar of the second church18th century, circa 1741

Batiscan (Quebec), Canada

Credits:

Credits:Collection of the Musée national des beaux-arts du Québec

10

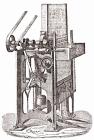

HOW ARE MATCHES MADE?

The wood - usually a soft essence such as aspen, poplar, birch or linden - is first cross-cut to a width equivalent to the length of a match. These pieces are dried in an oven and then fed into a special machine that cuts them into matches. A plane composed of 50 sharp dies moves back and forth and, depending on the shape of the dies, cuts out 50 round, square or fluted matches in the piece of wood.

11

Step 119th century, circa 1875

Batiscan (Quebec), Canada

Credits:

Credits:Archives of the Fondation des Amis du Vieux presbytère de Batiscan

12

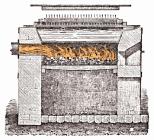

Afterwards, the sticks are placed in wooden frames. These are then set in vertical presses and maintained at equal distance by a series of wooden strips. Once held in place in this way, the matches are dipped into a bath of sulfur and paraffin wax.

13

Step 219th century, circa 1875

Batiscan (Quebec), Canada

Credits:

Credits:Archives of the Fondation des Amis du Vieux presbytère de Batiscan

14

While still inserted in their wooden frame, the matches are dipped into a chemical paste. The paste is spread in a thin coat over a hot plate heated by a double-boiler to be maintained in a semi-liquid state. The wooden frame containing the sulfur impregnated matches is applied on the plate and each stick is coated with a few millimeters of paste.

15

Step 319th century, circa 1875

Batiscan (Quebec), Canada

Credits:

Credits:Archives of the Fondation des Amis du Vieux presbytère de Batiscan

16

This chemical paste's composition could vary slightly, but it usually was a combination of phosphorus and another flammable element. Less frequently, a mixture of combustible materials was used without phosphorus. These matches however, could not be ignited by friction. They had to be coupled with a striking strip coated with a thin layer of amorphous phosphorus.

17

Step 419th century, circa 1875

Batiscan (Quebec), Canada

Credits:

Credits:Archives of the Fondation des Amis du Vieux presbytère de Batiscan

18

Finally, the frames of matches are placed on heated and ventilated racks so that the chemical paste dries. Once dry, the matches are taken off the frames and packed in boxes.